(VA-) RTM

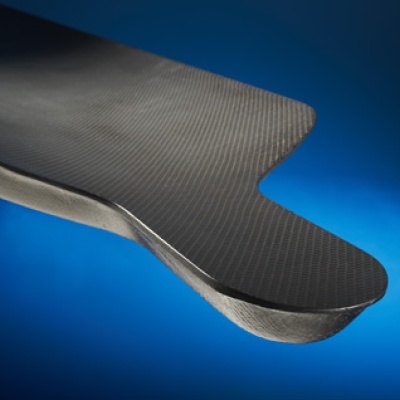

Resin Transfer Moulding (RTM) is an advanced manufacturing process in which a 2-component resin is injected into a pre-processed mould containing a package of dry fibres. This process begins with preparing the mould and placing the dry fibres. The resin is then injected into the mould under pressure, fully impregnating the fibres. After a certain period and at a specific temperature, the resin polymerizes, resulting in a strong and durable composite product.

Vacuum Assisted RTM (VA-RTM) is a variant of the RTM process that uses vacuum to draw the resin into the mould. This is particularly useful for producing large products (>1 m²). The vacuum helps to remove air bubbles and ensures better distribution of the resin, leading to a higher quality end product.

High mechanical properties

Suitable for large and complex products

Ideal for small to medium quantities

No or minimal post-processing required